Key challenges

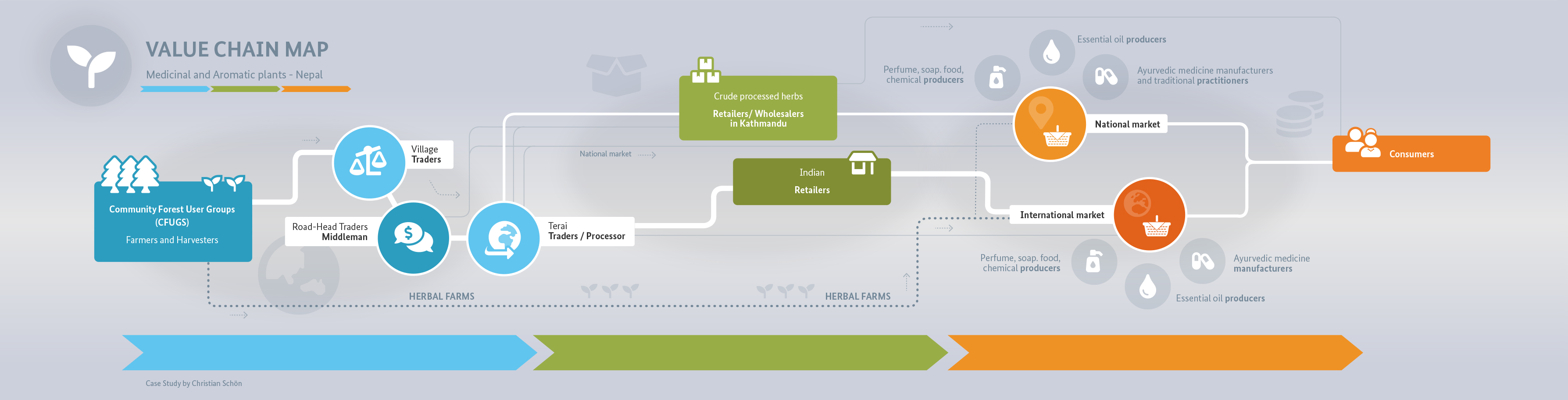

MAPs are Nepal’s major export goods. Nepal's exports of MAPs and plant-based products amounted to about USD 12,000,000 in 2012 and 2013. Collection, processing (mostly into essential oils) and trading of MAPs have created employment opportunities and generated income in remote rural areas, particularly in the provinces Sudurpashchim, Karnali and Province 5. Nonetheless, there is still considerable untapped growth potential. In particular, failure to embrace good agriculture, harvesting and manufacturing practices is a significant shortcoming that will need to be addressed if the requirements of highly demanding and lucrative markets are to be met. Furthermore, a functioning Quality Infrastructure (abbreviated to QI) system is essentially absent in Nepal in respect of MAPs and in many other sectors.

At the same time, demand for more and better QI services has been expressed by actors in the MAPs value chain. Up to this point, the Department of Plant Resources (DPR) has only offered basic tests on essential oils and their raw materials. The Gesellschaft für Internationale Zusammenarbeit (GIZ) – which supports the MAPs value chain – was able to demonstrate clear quality gaps.

Most of the exporting firms market MAP products to India and China. Few companies export MAPs and processed products to third countries. The exporters are mainly located in Nepalgunj, Krishnanagar and Kathmandu.

Host organisation

Department of Plant Resources (DPR)

Development partners involved

The GIZ project Inclusive Development of the Economy (INCLUDE)

Value chain analysis: Intervention areas and main quality gaps

Input

- Collectors lacking knowledge of Good Agriculture Practices and Good Harvesting Practices

- A cultural mindset that holds back the use of technology

- Lack of certified organic inputs

- Lack of adequate testing facilities

Planting and harvesting

- Lack of certified planting materials

- Errors in plant identification and grading

- Absence of technical regulations concerning harvesting

- Pollution by chemicals

Processing

- Lack of adequate equipment and technology

- Limited technical skills among the workforce

- Uncertainty over the availability of raw materials

Export

- Local testing facilities are not accredited

- No accreditation body in Nepal

- Lack of certified packing materials

- Lack of testing facilities to screen for pesticides and allergens

- Good Practices: Documentation on the three types of Good Practices: Good Agriculture Practices (GAP), Good Collection Practices (GCP) and Good Manufacturing Practices (GMP)

- Metrology and Calibration: Calibration in distilleries (in respect of mass, pressure, temperature and volume) and laboratories (in respect of mass and temperature)

- Standards: Forming a permanent technical committee for MAPs and essential oils

- Laboratories:

- Collaborative Test (ILC) with Nepali and foreign buyers (refractive index, optical rotation, specific gravity (threefold criteria) for lemongrass oil)

- Confirmation of testing standards used as required by buyers

Overall, the first Calidena exercise in Nepal was considered successful, as it yielded a variety of expected and unexpected results.

As per usual, the Calidena action plan includes undertakings that can be implemented and are able to show results within a short timeframe (3 to 6 months), which can be started immediately and without substantial further funding. Important QI areas are covered (Metrology and Calibration, Standards, Laboratories). The additional Good Practices fields, e.g. Good Collection Practices (GCP) and Good Manufacturing Practices (GMP) refer to quality management at industry and enterprise level. It is considered important to enable firms to articulate demand for QI services.

From a QI perspective, the results measured consist of 6-8 standards that were developed, accreditations secured for a number of laboratories, proficiency testing (PT) schemes put in place and the organisation of an inter-lab comparison of DPR laboratories.

Among those results, the PT results for aromatic oil extraction, laboratory accreditation and the ability to produce several standards were rather unexpected.

In addition, cooperation between the Nepal Bureau of Standards and Metrology (NBSM) and DPR developed very effectively thanks to Calidena, which continued to support standards development.

LESSONS LEARNED

For the Value Chain

- Lack of knowledge about the technical production process and the interlinkages in the value chain could make value chain support difficult

For the QI in the country

- Lack of knowledge about the technical production process and the interlinkages in the value chain could make Quality Infrastructure support difficult

For the Calidena method

- The bigger the network of stakeholders involved, the more complex the situation in which a Calidena process must be implemented

- Calidena needs sufficient time and funding to be successful. In Nepal, both of these requirements were met

- The end of the process needs to be considered from the very beginning (exit strategy). The roles of the partners involved should be clearly defined when supporting the value chain and managing interventions

- It remains a challenge to raise awareness and improve private sector understanding of the potential benefits of the process

- From a PTB perspective, collaboration with GIZ programs can be useful, as it facilitates the identification of value chains and key stakeholders. GIZ is able to cover a broader scope of undertakings (beyond QI) and can focus on implementing undertakings related to processes within value chains

Available Resources

- Final workshop documentation (2014)

- DPR minutes of debriefing (2014)

- Consultant report on Calidena workshop (2014)

- MAPs feasibility study (MAPs QI report) (2013)

- Minutes of Calidena workshop (2014)

- Presentation of follow-up workshop (2015)

Timur – Spice of Nepal, video (2016), » Video

Author: Christian Schön